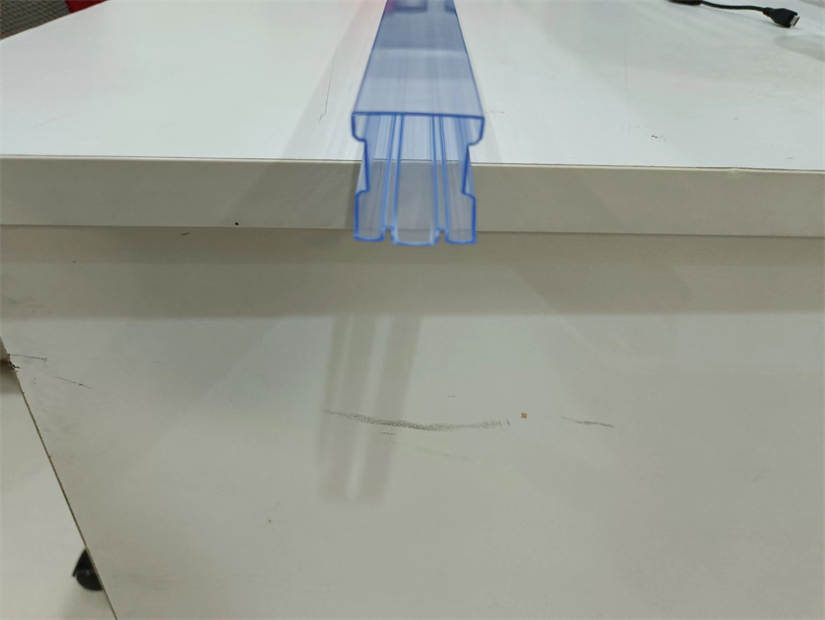

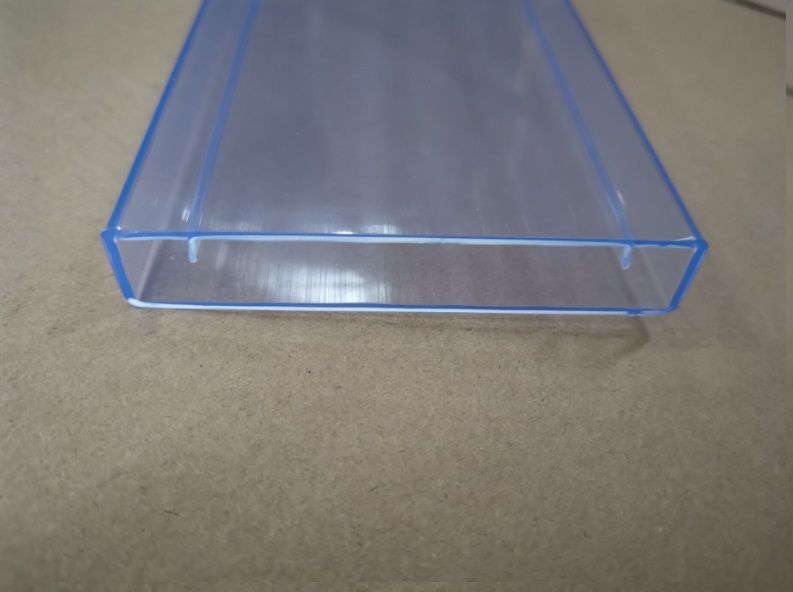

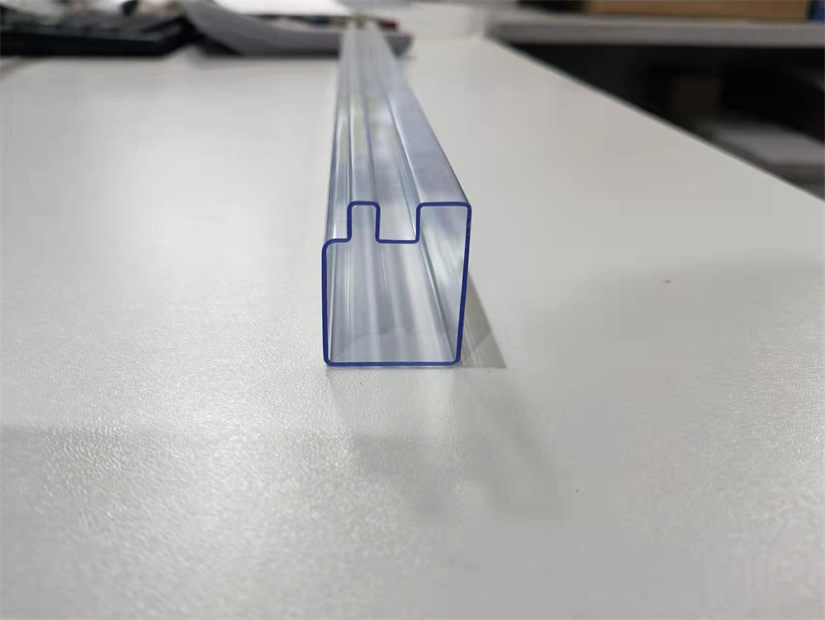

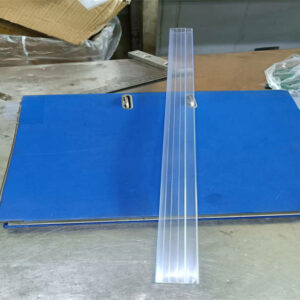

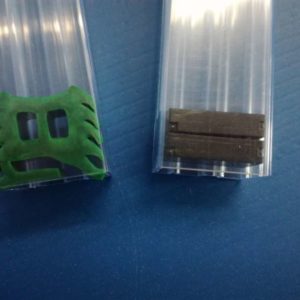

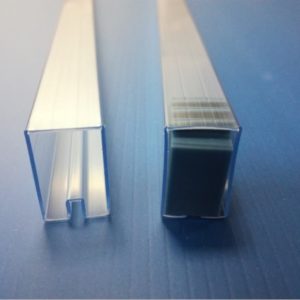

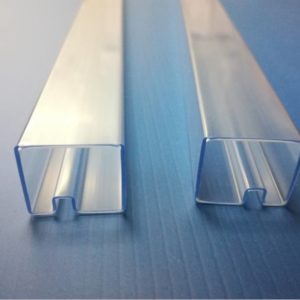

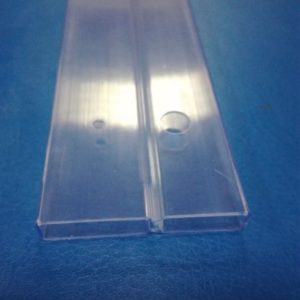

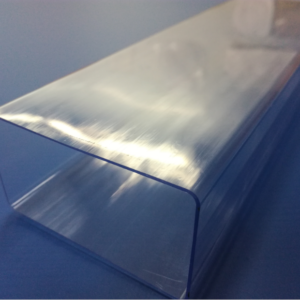

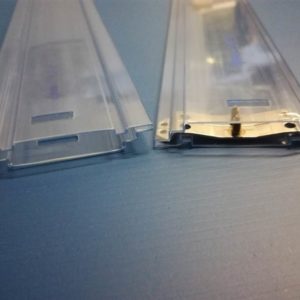

SEWATE specializes in a wide range of Custom IC Tubes for almost every application you can think of. Our custom tubes can be customized in terms of material, length, color, shape and level of anti-static requirements!

Common custom tube questions are answered below.

(1) Tooling Cost | (2) Tooling Cost Factors | (3) Custom Tube Type | (4) Design Process (5) Lead Time

Custom Plastic tube tooling Cost

Custom plastic tube tooling start at $1200 for small tubes in low volume applications. It increases according to complexity and size.

Custom IC Tube Tooling Cost Factors

The complexity of the tube, the size of the tube and the material used for the tube. Some materials, such as polycarbonate and polypropylene, may require more sophisticated tooling.

Tools are maintained throughout the life of the program.

Design Process for Custom IC tubes

A typical process follows some or all of the steps mentioned below. These steps help ensure that the tube is working properly when the process is complete.

- Free Quote. This involves a review of the application, key design requirements and tube functionality. The specific design process will be indicated in the estimate.

- Using the purchase order, create a drawing for approval. This step helps ensure that the tube is as expected and serves as an opportunity to make adjustments and/or changes to the design.

- Mold making and Tooling trial

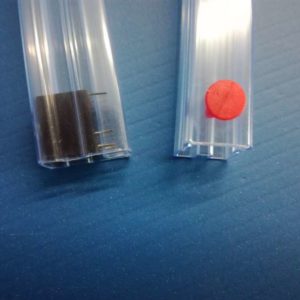

- Sample production, free samples of 20-50 tube will be provided

Custom IC Tube Lead Time

The time to Custom IC Tubes depends on many factors. 25-day ARO on the low end if the project is basic and low volume. Typical lead time is 4-6 weeks. This time may increase if changes are made during the design process. Lead times for complex tools or high volume items can be as high as 10-12 week

Read more: Anti Static IC Shipping Tube customization guidelines

Read more: What are the materials for Custom ESD Tubes?