Description

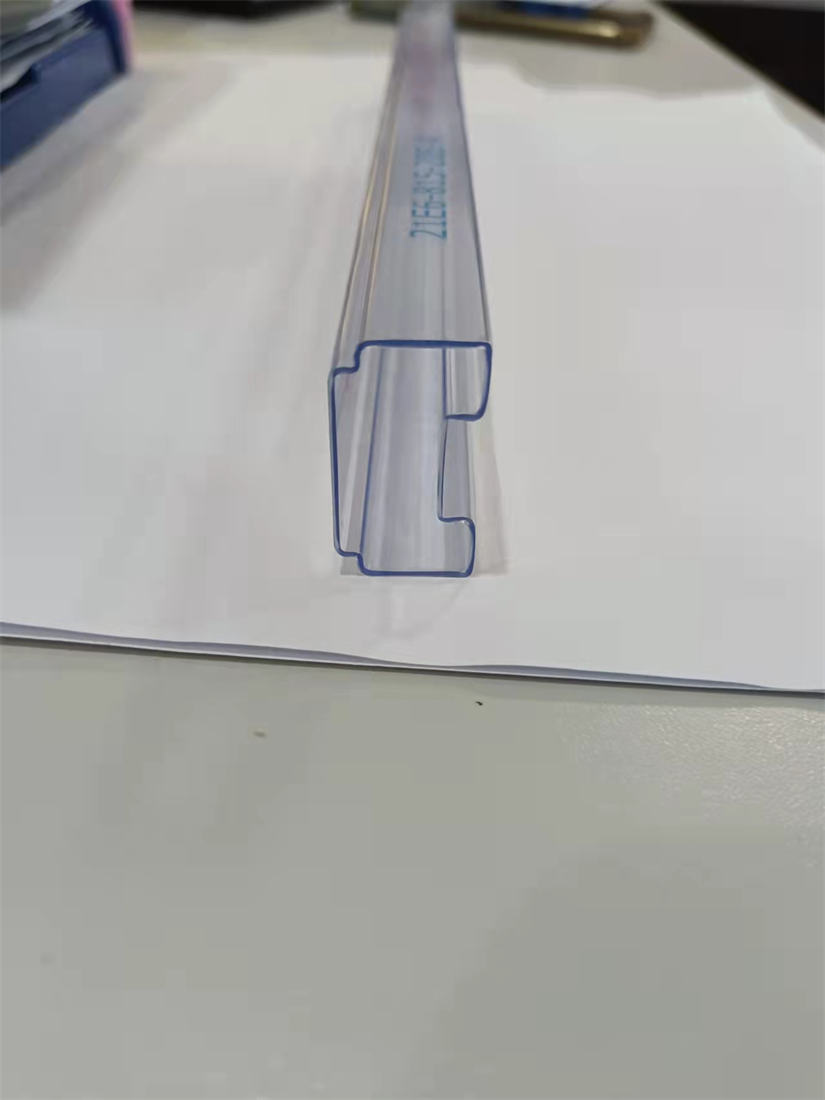

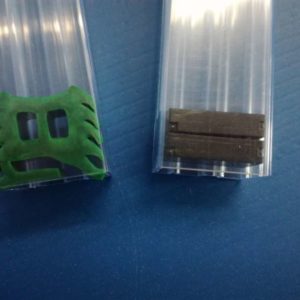

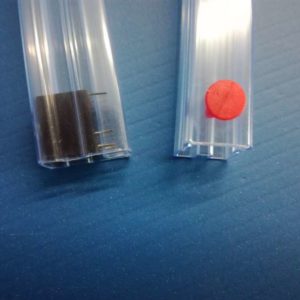

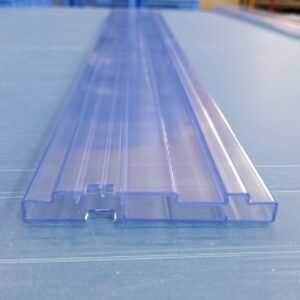

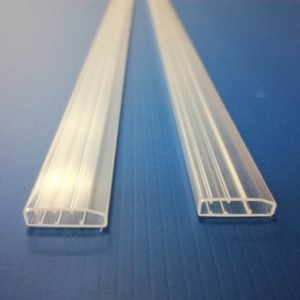

Standard or custom made AntiStatic IC Tubes used for packaging electronic components, protecting them from the dangers of ESD, transportation and atmospheric damage.

SOP, SSOP, TSSOP TUBE Family:

MSOP Tube – 150 Mil SOP Tube

32 Lead SOP Tube – 450 Mil SOP Tube

350-400 Mil SOP Tube – 350-450 Mil SOP Tube

220 SSOP 5.3mm Tube – 4.4 mm TSSOP Tube

220 Mil TSSOP Tube

32 Lead SOP – 44 Lead TSOP – 450 Mil SOP – 490 Mil TSOP – 350-400 Mil SOP

8 Lead EIAJ/SSOP – Mini SOP antistatic plastic storage tubes

350SOP, 450SOP, 4.4TTSSOP, 150SOP, 220SSOP, 220TSSOP, 32SOP, 44TSOP, 450SOP, 490SOP, 350SOP, 400SOP, 8SSOP

Body Width

SO 150 mils (3.9mm)

SOP 208 mils (5.3mm)

SOM 220 mils (5.6mm)

SOL 300 mils (7.5mm)

SOW 330~350 mils (8.4~8.9mm)

SOX 400 mils (10mm)

SOY 450 mils (11.4mm)

SOZ 525 mils (13.3mm)

_________________________________________________________________________________________________________________________________

STANDARD PVC

The semiconductor industry has relied on shipping tubes as the primary medium for shipping its components between assembly and test operations or between its end customers. There are still two simple reasons for its popularity – economy and flexibility. We offer over a thousand types of open tools, from through-hole, SMT to leadless packaging (QFN, MLF, LPCC, etc.). Our products can provide services for the following fields, such as connectors, relays, switches, power modules, sensors, medical instruments, leds, passive components and so on.

| Features | Benefits |

| Good impact strength | crack free tubes |

| Stable dimension | Excellent smooth interfacing |

| Critical dimension control within 5 mils | Higher productivity |

| Short cycle time | Short lead time |

POLYCARBONATE(PC)

Polycarbonate SOP tube is our high performance shipping tube series. Our deep knowledge of shipping tube design, polymer science and extrusion technology enables us to produce shipping tubes with tolerances of +/ -2 mil (+/ -50 micron) dimensions. This unique tight tolerance can help many of our customers improve uptime, reduce scrap and minimize rework.

| Features | Benefits |

| Tight tolerance. Critical dimension control +/- 2 mils | Accurate unattended high speed device loading and unloading |

| Superb clarity/transparency | Ease of visual inspection |

| Package guide profile design | Prevent device piggy back, shingling and unit rotation |

| High impact strength | Ideal for MSOP and TSSOP square body packages |

“Green materials”

Actively support the 3R concept – reduce, reuse and recycle.

We are always looking for opportunities to launch products that help reduce the impact on the environment. Various “green materials”, such as PS, PC and PETG polymer products, are testament to this commitment.

PS SOP TUBES

| Features | Benefits |

| Halogen free | Reduced environmental impact |

| Improved clarity/transparency and impact strength | Good clarity/transparency without compromising impact strength |

Available in clear or translucent |

PETG SOP TUBES

| Features | Benefits |

| Halogen free | Reduced environmental impact |

| Strongest impact strength | Excellent for heavy duty big packages |

Excellent clarity/transparency | Application examples: microprocessor heat sink and ceramic TO packages. |

Read more: How to store the IC tubes

Did you get more details for AntiStatic Tubes? Jump straight ahead and read SOIC, SOJ TUBES and DIP SHIPPING TUBES

Or contact us in Linkedin to learn more information.