Does the supplier have the ability to develop and design IC tubes?

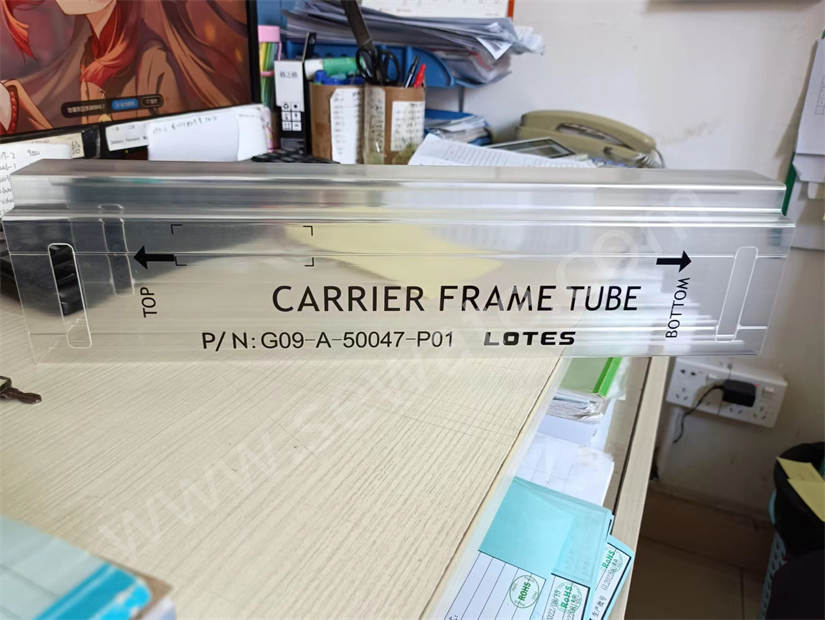

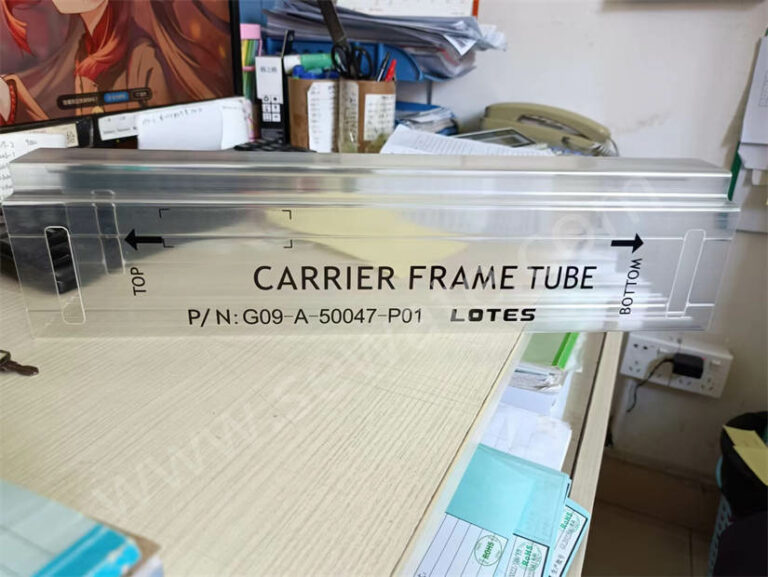

Yes. Sewate has 20 years of research and development and design capabilities for IC tubes. The R&D and design capabilities of the supplier are critical. Independent R&D and design capabilities are necessary factors in designing an Anti-static IC tube that meets the requirements. A good supplier can design a shipping tube that meets the requirements by simply providing a part drawing or the real part samples.

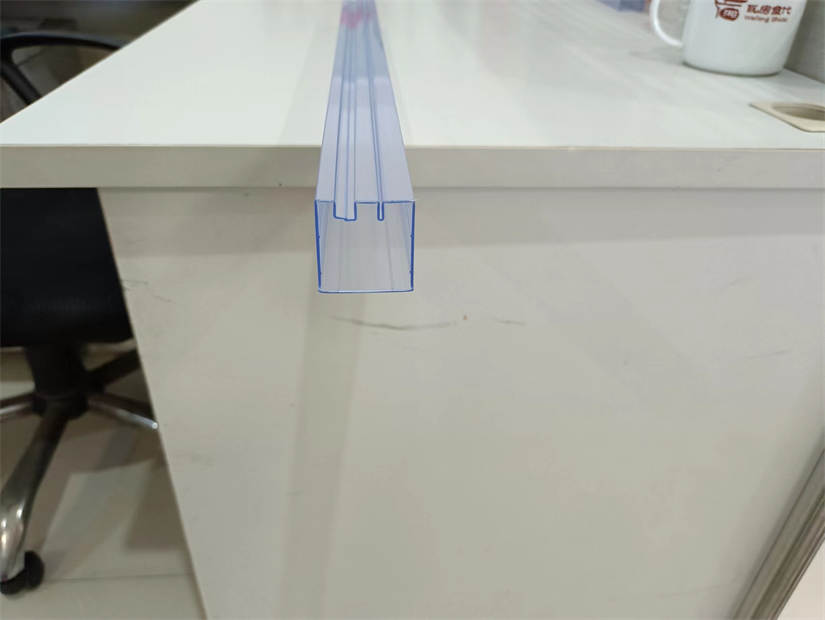

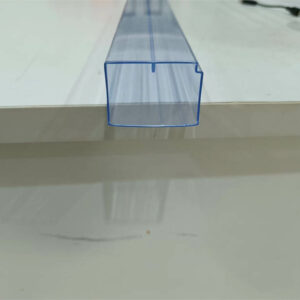

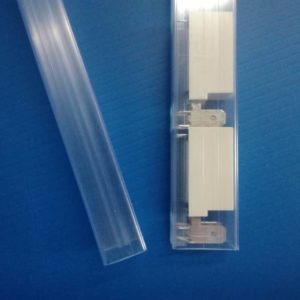

Will IC tubes get stuck during the packaging process?

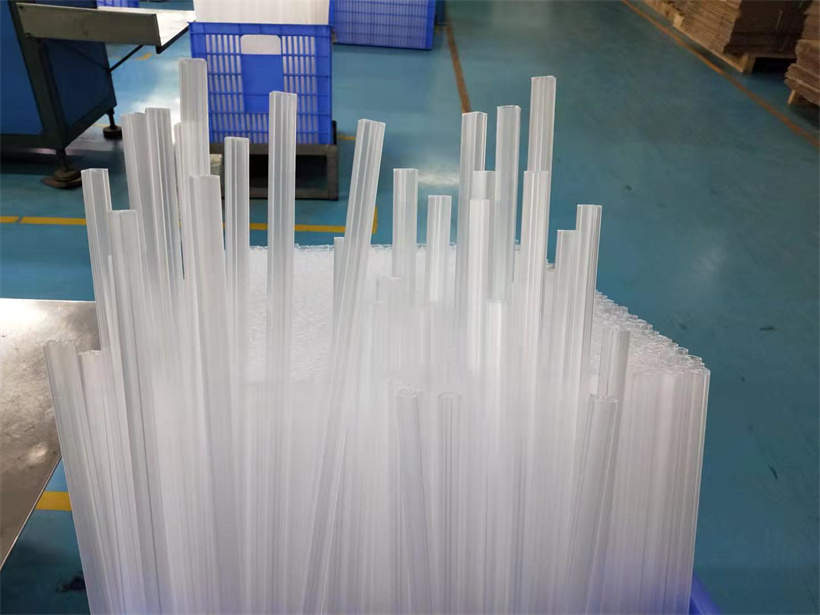

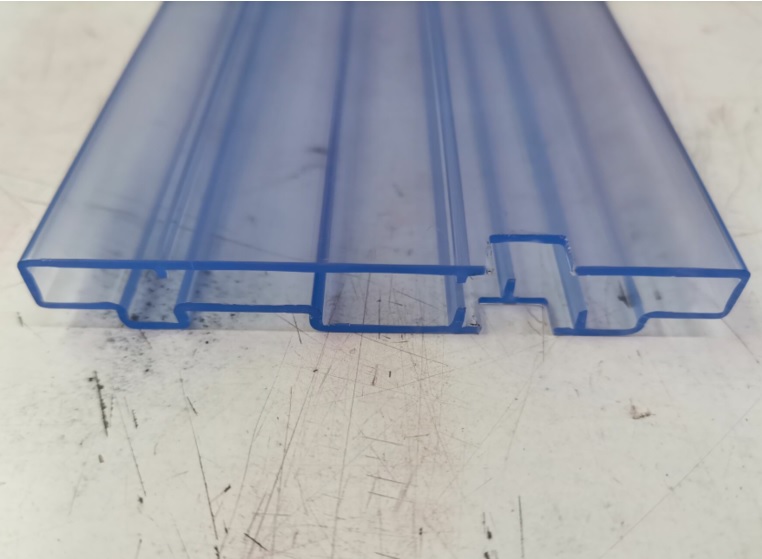

The IC Tubes designed and produced by our company is more suitable for automatic assembly line packaging because of its reasonable design, stable production process, and well-controlled dimensional precision which may effectively prevent parts jamming. At the same time, we have established a complete inspection system And quality management system to ensure product performance.

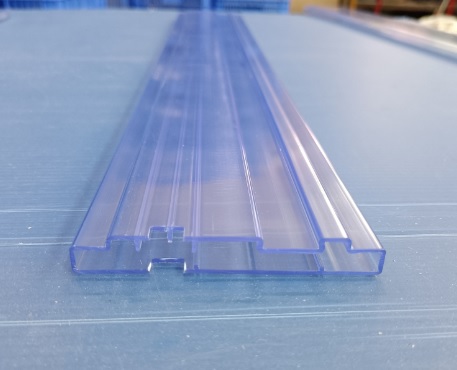

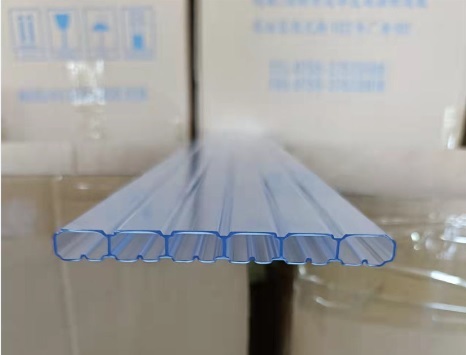

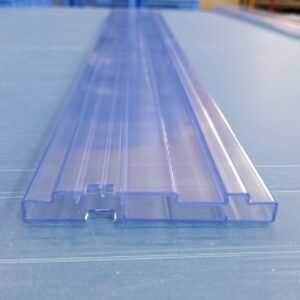

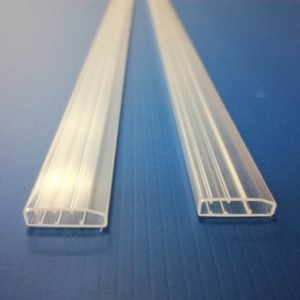

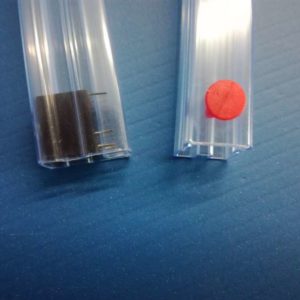

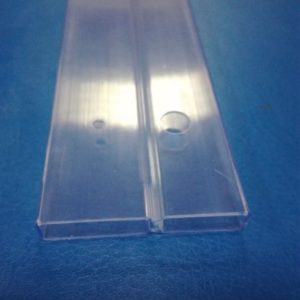

Is the transparency of the IC tubes good?

Yes, The IC tube produced by our company has high transparency, no impurities and burrs, which is beneficial for customer staffs to check the quality of the parts inside through the tubes.

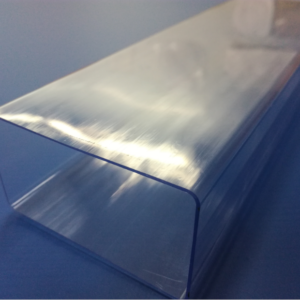

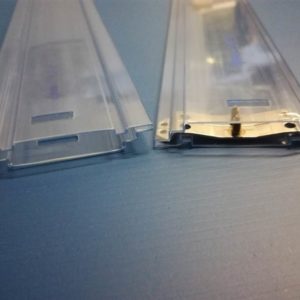

The IC tubes are easy to crush the components during transportation? Can it better protect the parts?

The IC tubes produced by our company has excellent elasticity, wear resistance and toughness, and is not easy to be damaged during transportation, so that it can better protect your parts.

What is the Lead Time of custom tube typically?

The time to Custom IC Tubes depends on many factors. 25-day ARO on the low end if the project is basic and low volume. Typical lead time is 4-6 weeks. This time may increase if changes are made during the design process. Lead times for complex tools or high volume items can be as high as 10-12 week.