With the increase of labor costs, the popularity of automated production lines, IC tubes, connector tubes, power module tubes, LED tubes, relay tubes, and other electronic components tubes are also becoming more widely used. Many small companies blindly pursue low-priced packaging materials, and there is no requirement for quality. When it is later discovered that the parts are stuck in the packaging process, they will regret it when they crush them during transportation. Shenzhen Sewate Technology Co., Ltd. tells you about six ways to identify quality anti-static plastic IC tubes.

1.Length:

See if the specified length has been reached. Some manufacturers rely on shortening the length to reduce the price. Manufacturers with a good reputation are not allowed to exceed the typical error.

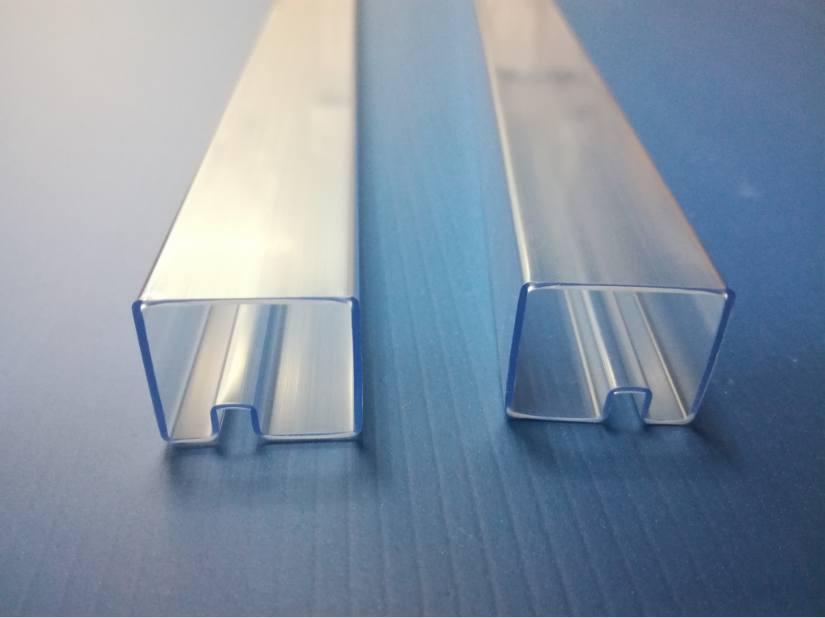

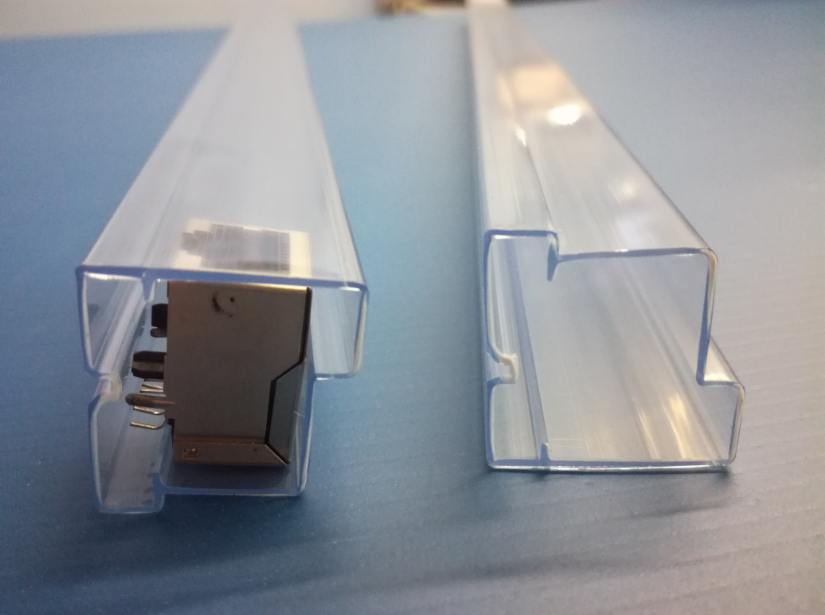

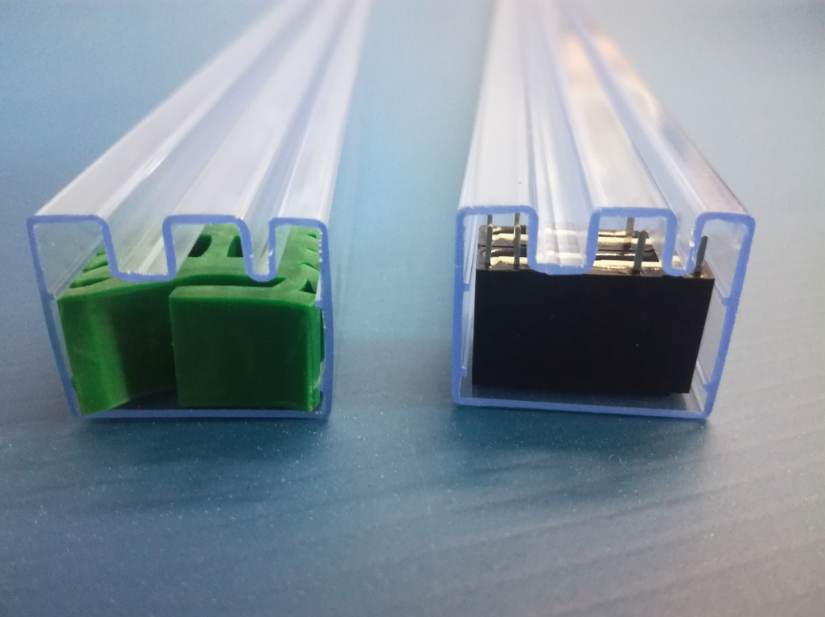

2.Quantity wall thickness:

See if the specified wall thickness is reached. Some tubes are evacuated, and the wall thickness at both ends meets the requirements, but the intermediate wall thickness is thin, which does not meet the requirements for use, and the cost is reduced by evacuation.

3.Weighing:

Take two plastic IC tubes of the same diameter, wall thickness, and length to compare the weight. The calcium powder and impurities with high weight are added too much, and the material is not pure, which does not meet the requirements.

Extended reading “What are the materials for Plastic anti static ic tubes?”

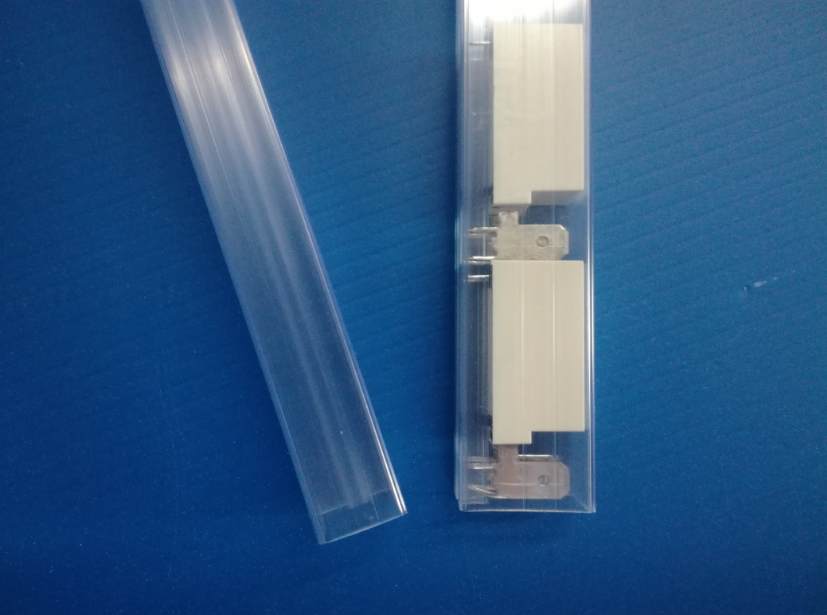

4.Look at the color:

The surface of the high-quality clear plastic tubes is bright and transparent. The blue color is a high-quality product. If it is pale, light yellow indicates that the manufacturer has added miscellaneous materials, recycled materials, waste, etc.

Extended reading “What are the factors that affect the appearance of IC shipping tubes?”

5.Fall:

Conditional when you can use your feet to step on the edge of the tube, to see whether it can be easily crushed. High-quality IC packaging tube with foot kick, or even rolled, will only be flat and not cracked, more will not be broken. Inferior IC packaging tube with a foot kick can be broken! Some manufacturers add excessive recycled materials and waste materials in tube production to save costs and improve profits. Such plastic tube is cheap, but its hardness will drop a lot, fragile. Such tubes will be defective.

6.Inspection:

The test report for the tube should be requested, preferably the original.